| 일 | 월 | 화 | 수 | 목 | 금 | 토 |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| 22 | 23 | 24 | 25 | 26 | 27 | 28 |

- 에어 액츄에이터

- PCB 동도금

- 알리 검전기

- PCB 제조 순서

- Cis

- fpcb

- FR2

- 히오키3480

- 히오키 검전기

- FR1

- CEM1

- pcb

- CMOS sensor principle

- Copper clad laminate

- FR4

- 라이프니츠 계산기

- CEM2

- FR3

- ccd 센서란?

- What is CCD Image sensor

- Image senser

- 애플 반도체의 역사

- 공압 실린더

- what is CMOS sensor

- copper

- CMOS Image Sensor (CIS)

- CCD sensor

- FMEA

- Plating

- What is ccd sensor

- Today

- Total

electronics world

What is FMEA? 본문

■. What is FMEA (Failure modes, effects, and criticality analysis) ?

FMEA is one of the first systematic techniques for failure analysis. FMEA was developed by the U.S. Department of Defense and the first guideline is [MIL-P-1629] “Procedures for performing a failure mode, effects and criticality analysis” established on November 9, 1949 in the U.S. Military Standard. FMEA is most often used as a reliability analysis technique in the early stages of system development. FMEA is usually performed at the concept or early design stage to identify all possible failure types and take appropriate actions to reduce failures.

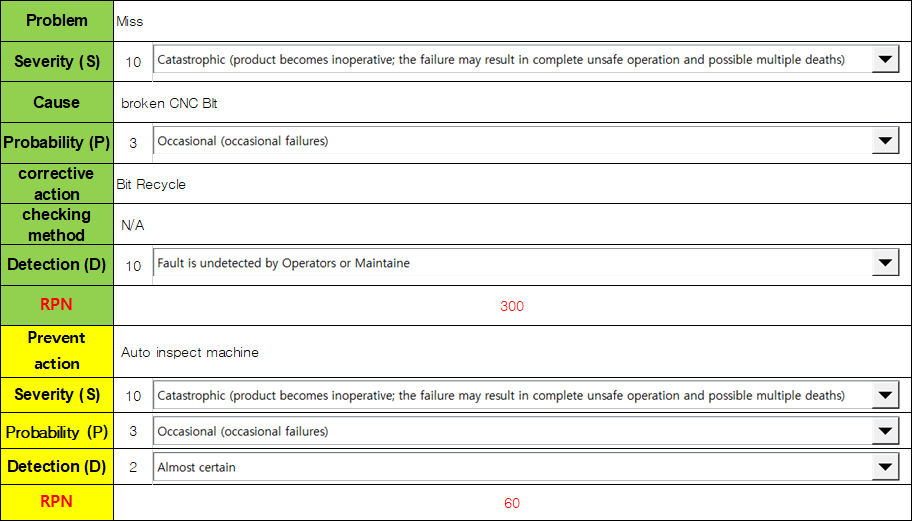

■. FMEA form

Usually, you can refer to the form below and modify it slightly for each company. The most important thing in FMEA is to actually do it. Manufacturing, quality, development, and design personnel should all gather to conduct FMEA on expected defects and take corrective actions according to risk priority (RPN).

I think the most important thing in FMEA is practice. There are many people who think that there is no big change in quality even if they are busy. If you organize a circle meeting and keep it for one year, there will be a big change in quality improvement, so please try it!!!

'Analytical technology' 카테고리의 다른 글

| 사전제품 품질계획 (APQP) Advanced product quality planning (0) | 2017.04.29 |

|---|